Portable Grit Blasting Machine

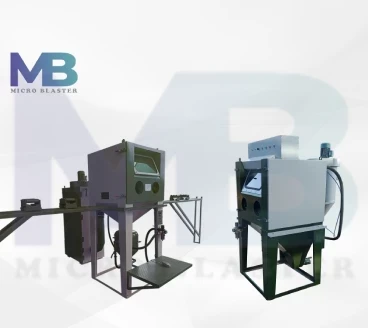

Portable Grit Blasting Machine used to soften rough surfaces, this machine removes rust or corrosion from metal surfaces, gives a surface clean or shaped using abrasive material known as media. There are many different types of grit blasting machines such as Portable Gritblaster, Automatic Grit Blaster, Grit Blast Cabinet, Tumblers, and many more.

A portable Grit Blasting machine is a machine that uses abrasive materials with air pressure to clean or prepare surfaces for painting. Grit blast can also be used for the destruction of sand, it is also used to remove contaminated substances from metal products. These have been cast or made forged and in some cases have been welded.

The media is put in a tank and air pressure is kept under the same pressure as the operator will do Portable Grit blasting Machine. The media is then dropped by gravity into a blast pipeline, which pushes it out of the blast nozzle, which is the pressure of the air we use.

Grit blasting machine is using in many industrial areas, construction, and even crafts. Glass is frosted with a grit blaster usually for design or artwork. Large ships are sandblasted to clean up the rust for repainting. Grit blasters are used in car restoration and old tractors and trucks to remove old paint & rust. Railroad cars are reconditioned by grit blasting the entire car to repaint. Many industries use the grit-blasting process for several purposes.

A Portable Gritblaster is often using by small and mid-sized industries such as Paint Shops, Auto Repair industry, Powder Coating Industry, Floor and Surface Cleaning Service Providers, and many more.

There are various types of media that can be used in grit blaster depending on the requirement and the surface that has to be smoothened, roughen, or cleaned such as Sand, stainless steel shots, cut wire shots, glass beads, steel shots, steel grits, copper slag, aluminum oxide grit and many other.

Grit blasting must be carried out with proper safety equipment in place and must be handled with care otherwise it can cause anaphylactic shock to the operator or the person getting in contact. So the operator must use grit blasting safety wear while working. It includes an operator’s suit, rubber hand gloves, gumboots, helmet, etc.

Manufacturing a portable grit blaster is not a complex process but it needs experience and knowledge of various abrasive media or materials and their application for cleaning different surfaces. We manufacture a Portable grit blaster and concern that is extremely affordable and highly reliable.

Keeping in mind the need for small and mid-sized businesses that are completely based on grit blasting for cleaning, etching, and removing contaminants from various types of metal and concrete surfaces in day-to-day life we have mastered the art of making portable grit blasters manufacturing in Jodhpur, India.

The cost of a portable grit blaster is efficient and it can be used for grit blasting purpose for cleaning large metal surfaces, steel structures, boiler, containers for sugar mill, alloy wheels, rusted pipes, concrete surfaces, old ships, floors, even for engraving on granite, woods, etc. and any other surface that needs to be cleaned, smoother or roughen.